Complete Guide to Cold Plating Film: The Best Solution for Protection and Enhancement

In today’s printing, advertising, and signage industries, high-quality post-processing solutions are crucial as they ensure the durability and visual effects of the image. Cold lamination film has become one of the most popular choices due to its high efficiency, economy, and ease of operation. Unlike hot mounting that requires heating, cold mounting film is firmly bonded to the surface of printed materials through pressure-sensitive adhesive, which not only protects the image but also enhances visual performance. This article will comprehensively analyze the definition, characteristics, applications, classification, production process, and supplier selection suggestions of cold laminating film for you.

Table of Contents

ToggleWhat is Cold Lamination Film?

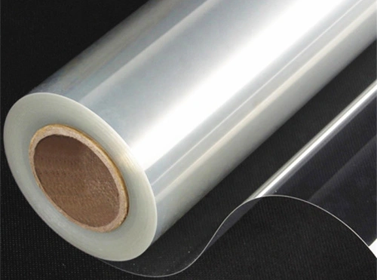

Cold laminating film is a transparent protective film made of PVC or PET substrate and coated with pressure-sensitive adhesive. When in use, the film can be applied to the surface of printed images, photos, or documents through pressure (without heating), forming a durable protective layer. Cold laminating film can prevent scratches, moisture, dust, and UV damage, extend material life, and enhance color brightness. Products are often supplied in the form of rolls, with different widths, thicknesses, and surface effects, which can meet the diverse needs of advertising, photography, packaging, and decoration fields.

Major Component

Substrate: commonly used PVC or PET to ensure strength and transparency.

Adhesive layer: Pressure sensitive adhesive, ensuring that it can be bonded without heating.

Release paper: protective adhesive layer, easy to operate.

The Main Advantages of Cold Laminating Film

The use of cold lamination film can bring multiple benefits to users, not only enhancing the visual effect of the image, but also providing comprehensive protection during use and storage. The following are its significant advantages:

Strong Protective Performance

Cold mounting film forms a transparent protective layer on the surface of printed materials, effectively blocking external environmental damage to the image

Waterproof and dustproof: Even in damp or dusty environments, the image can still remain clean and intact.

Anti fouling and scratch resistant: reduces the marks caused by finger touch, scratching, friction, etc., making the image always smooth and new.

UV resistance: Especially suitable for outdoor advertising and display screens, it can significantly reduce fading and aging caused by sunlight exposure, and extend the service life.

Visual Enhancement

Cold laminating film is not only a protective material, but also a “color enhancer” for the visual effect:

High definition transparency: High transparency materials will not obstruct or affect the original image, making the image details clearer.

Full color: Bright film can increase color contrast, making the picture more vivid and bright; Matte film provides a soft and professional texture.

Multiple choices: Special surfaces such as sand surface and textured film can create unique visual effects, meeting the different needs of advertising, art, and high-end display.

Easy to Operate

Compared to hot mounting, the use of cold mounting film is more flexible:

No heating required: Film coating can be completed through pressure-sensitive adhesive without the need for additional heating equipment.

Equipment compatibility: Both manual laminating machines and automatic large format laminating machines can be easily adapted.

Safe and reliable: Avoid deformation, curling, or fading of thermal printing materials (such as inkjet prints and thermal paper) caused by high temperatures.

Durable and Long-Lasting

Cold laminating film is not only a temporary protection, but also can extend the overall lifespan of the image:

Wear resistant and durable: The surface has excellent wear resistance, suitable for display screens in frequently touched or high flow areas.

Adapt to multiple environments: Whether it’s indoor display or outdoor advertising, it can maintain a stable protective effect.

Extend lifespan: Ensure that the image remains clear and brightly colored even after prolonged display.

Economical and Affordable

Cold laminating film is not only practical, but also cost-effective:

Energy saving: Unlike thermal mounting, there is no need to consume electricity for heating, greatly reducing energy consumption.

Reduce equipment costs: Easy to operate, no need for expensive laminating machines.

Improve efficiency: Fast installation, suitable for post-processing of large quantities of advertisements and printed materials.

Environmentally Friendly

With the increasing awareness of environmental protection, the materials and processes of cold laminating films are constantly optimized

Environmentally friendly adhesive: Some products use solvent-free or environmentally friendly pressure-sensitive adhesives, which are healthier and safer.

Recyclable substrate: High quality PET cold laminating film has recyclable properties and meets the needs of sustainable development.

Low energy consumption process: No heating required, reducing carbon emissions and being more environmentally friendly.

Classification of Cold Laminating Film

Cold laminating films can be classified based on surface effect, thickness, adhesive type, and substrate material.

According to the Surface Effect

Bright film: with bright colors and high brightness, suitable for advertising images.

Matte film: non reflective, anti fingerprint, commonly used for high-end displays.

Sand facial mask: anti glare, wear-resistant, suitable for display boards and artistic effects.

Special texture film: such as holographic, embossed, anti graffiti, etc.

By Thickness

20-30 μ m: Lightweight protection, suitable for indoor posters.

40-60 μ m: Conventional thickness, suitable for most advertising images.

80-100 μ m and above: Thick and durable, suitable for long-term outdoor display.

By Adhesive Type

Permanent adhesive: Strong adhesion, long-lasting durability.

Removable adhesive: can be adjusted or removed multiple times without damaging the image.

UV resistant adhesive: suitable for outdoor applications, providing additional protection.

By Material

PVC cold laminating film: good flexibility, moderate price, commonly used in the advertising industry.

PET cold laminating film: higher transparency, better strength, suitable for high-end applications.

How to Choose the Appropriate Cold Laminating Film

When choosing cold laminating film, the following factors should be considered:

Application scenarios: indoor or outdoor, short-term or long-term.

Surface effect: Bright light enhances color, matte avoids reflection, and sand surface enhances texture.

Thickness requirement: Thin film is lightweight, thick film is more durable.

Adhesive type: Permanent adhesive is suitable for long-term use, and removing adhesive is suitable for temporary display.

Budget and Quality: High quality products have a longer lifespan and higher cost-effectiveness.

Conclusion

Cold lamination film, as an important consumable in the fields of advertising, printing, signage, and decoration, not only effectively protects the image, but also enhances visual effects and service life. With diversified thickness, surface effect, and adhesive selection, cold laminating film can meet various needs of different industries.

If you are looking for a high-quality cold laminating film supplier, we can provide you with a one-stop solution. Please feel free to contact us at any time.