Double Sided Tape: A Ubiquitous Solution for Strong Adhesion

In daily life and industrial production, a seemingly simple yet crucial material silently plays a huge role – Double Sided Adhesive Tape. As a professional manufacturer of double-sided tape, we are well aware of the strong potential and wide applications of this product. This article will take you on a deeper understanding of the world of double-sided tape, exploring its diverse types, outstanding advantages, and infinite potential application scenarios.

Why Choose Double-Sided Tape? An Irreplaceable Advantage

Efficient and Convenient:

Core statement: Double sided tape represents “instant productivity”. It completely abandons the lengthy process of mixing, applying, and waiting for solidification of traditional liquid adhesives. There is no need for tedious processes such as drilling, tapping, and tightening like mechanical fixation.

Professional expression: On the production line, this means a great simplification of the process. Workers only need to tear open the release paper, accurately locate it, and apply pressure to complete the bonding, significantly increasing the output per unit time. For example, in the assembly of automotive interior parts and electronic devices, the application of double-sided tape can shorten the assembly time by several times. Reduced reliance on skilled workers, reduced backlog of work in progress caused by solidification waiting, and accelerated the efficiency of the entire supply chain.

Invisible Beauty:

Core statement: Double sided tape is an invisible contributor to achieving “seamless design” and “perfect appearance”.

Professional performance: It completely eliminates visual defects caused by screw holes, rivet heads, solder joints, or liquid glue overflow. In high-end consumer electronics products such as ultra-thin smartphones and frameless displays, double-sided tape is the key to achieving precise internal component fixation and seamless shell bonding, ensuring a clean and high-end appearance of the product. In building curtain walls and interior decoration (such as metal decorative strips and signage installation), it provides a smooth and seamless bonding effect, perfectly fitting the modern minimalist design concept. For designers, it releases the freedom of product appearance design, eliminating the need to reserve positions or cover fixed points.

Uniform Force:

Core statement: Double sided tape achieves large-area and continuous stress distribution, which is a core advantage that point fixation (screws/rivets) cannot match.

Professional manifestation: Mechanical fastening points can generate local high stress concentration, especially when subjected to vibration, impact, or thermal expansion and contraction, which can easily cause micro cracks, deformation, and even fracture of the adhered material around the hole (such as brittle materials such as glass and acrylic). The double-sided tape transfers and disperses the load through its entire adhesive surface, significantly reducing the peak stress per unit area. This not only protects the integrity of the bonded material, prolongs its service life, but also improves the reliability and safety of the bonded structure under dynamic loads (such as car body panels, aircraft interior parts).

Shock Absorption and Buffering:

Core statement: Double sided adhesive tape represented by foam substrates (such as PE, PU, acrylic foam) provides excellent energy absorption capacity.

Professional performance: This type of tape can effectively absorb and dissipate impact energy, and isolate vibration transmission. The automotive industry, it is widely used in door trim, bumpers, interior parts, wiring harness fixing, etc., to reduce driving noise (NVH control) and improve ride comfort. In electronic devices such as hard drives and precision sensors, it can protect sensitive components from damage caused by shock and vibration during transportation or use. In heavy machinery and building structures, relative motion between components can also be buffered, reducing wear and noise. This is a performance that is difficult to achieve with rigid mechanical fixation and most liquid adhesives.

Core Product Line of Professional Double-sided Tape Manufacturer

We focus on researching and manufacturing various high-performance double-sided tapes to meet the demanding needs of different industries

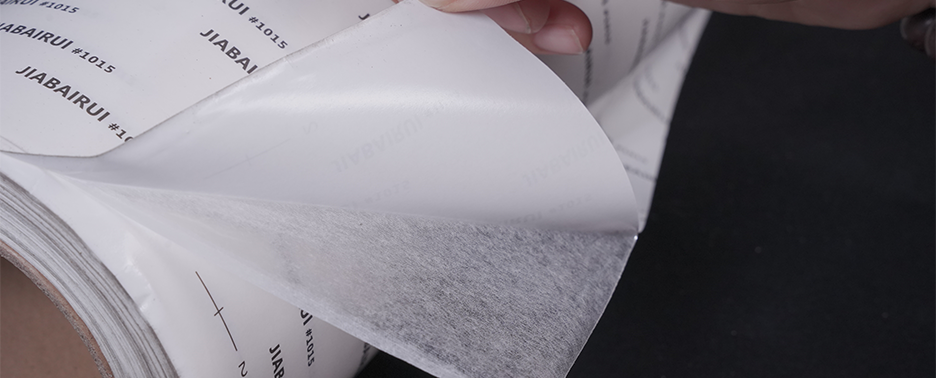

Transfer Tape without Substrate:

Features: Pure adhesive film, extremely thin, with excellent flexibility.

Application: Precision electronic component fixation, nameplate pasting, film bonding, splicing, etc.

Double Sided Film Tape for Film Substrate:

Common substrates: PET (polyester), PP (polypropylene), PVC, etc.

Features: Thin thickness, stable size, good temperature resistance, and not easily deformed.

Application: Screen assembly for mobile phones/tablets, touch screen lamination, FPC fixation, die-cutting processing, etc.

Foam Tape for Foam Substrate:

Common foam: PE (polyethylene), PU (polyurethane) EVA、 Acrylic foam, etc.

Features: Excellent gap filling ability, cushioning and shock absorption, sound and heat insulation, strong adhesion, and adaptability to rough surfaces.

Application: Automotive interior and exterior parts (decorative strips, signs, sealing strips), installation of building curtain walls, elevator cars, home appliance casings, fixing of sound insulation materials, etc.

Cloth/Paper Tape:

Features: Easy to tear, good initial adhesion, low cost.

Application: Carpet laying, paper bonding, lightweight packaging, handicraft production, temporary fixation, etc.

Specialty Tape:

VHB tape: Strong adhesive strength, partially replaceable for welding/riveting.

Thermal/conductive tape: meets the needs of heat dissipation or conductivity.

High temperature resistant tape: Suitable for high temperature environments such as engine compartments.

Removable tape: seamless adhesion, suitable for scenarios such as notices and temporary fixation.

Key Considerations for Choosing Double-sided Tape:

As a professional manufacturer, we deeply understand the importance of selecting the right product. When choosing double-sided tape, please be sure to consider:

Adhesive material: The material of the adhesive surface (metal, plastic, glass, etc.) and its surface energy (whether it is easy to adhere).

Usage environment: temperature range, humidity, exposure to chemicals, UV radiation intensity, etc.

Force requirements: The type and magnitude of stress to be borne (shear force, peel force, tensile force).

Thickness and gap filling: Whether the adhered surface is flat and how large the gap needs to be filled.

Operation requirements: whether high initial adhesion is required, whether rework is allowed, and whether easy tearing is required.

Final performance requirements: Whether special properties such as conductivity, thermal conductivity, flame retardancy, shock absorption, insulation, etc. are required.

Commitment of Professional Double-sided Tape Manufacturer

As a professional manufacturer with years of experience in the industry, we not only provide a complete range of reliable double-sided tape products, but also are committed to:

Continuous innovation: invest in research and development efforts to develop high-performance new products that meet the needs of emerging industries such as new energy and flexible displays.

Strict quality control: Implement an international standard quality management system to ensure stable and reliable performance of each roll of tape.

Customized service: Provide customized solutions based on customers’ specific application scenarios, sizes, colors, and performance requirements.

Technical support: Provide professional technical consultation and bonding solutions to help customers optimize their process flow.

Stable supply: Strong production capacity ensures timely and sufficient supply of goods.

Double Sided Tape: Connecting Infinite Possibilities of Invisible Power

From the exquisite assembly of smartphones to the smooth driving of cars; From the magnificent curtain walls of modern architecture to the warm decorations in homes, double-sided tape is everywhere, serving as an “invisible hero” connecting the modern world.

Choosing a professional double-sided tape manufacturer means choosing:

Reliable adhesive performance: Ensure that your product is sturdy and durable.

Optimized production efficiency: simplifying processes and reducing costs.

Innovative solutions: addressing complex challenges and realizing design possibilities.

A trustworthy partner: providing full process technical support and services.

Contact us immediately for the most suitable professional solution for your application needs! Let our strong adhesive strength help your products and projects move forward steadily!