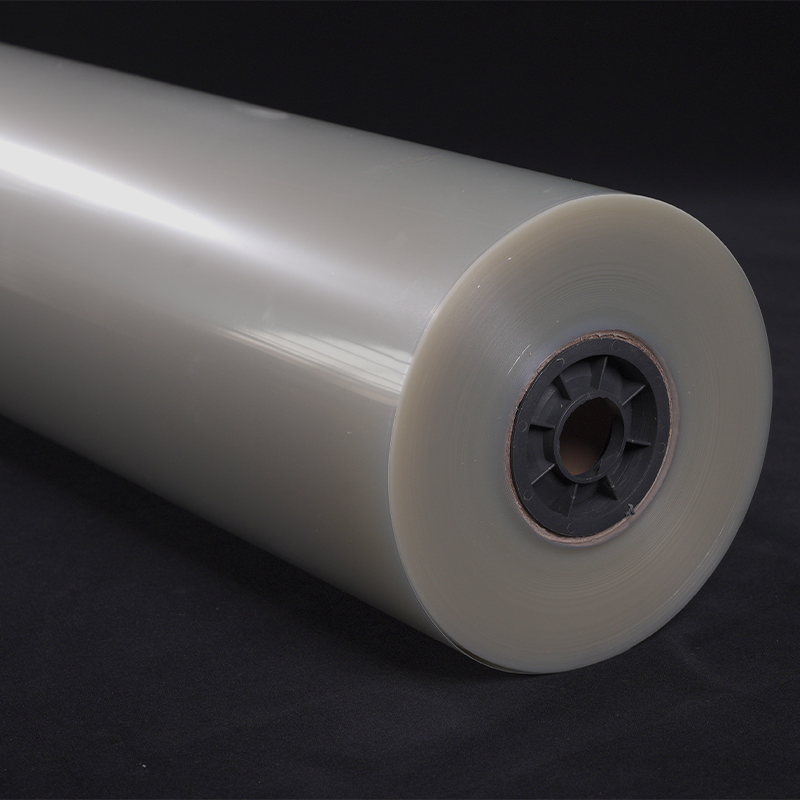

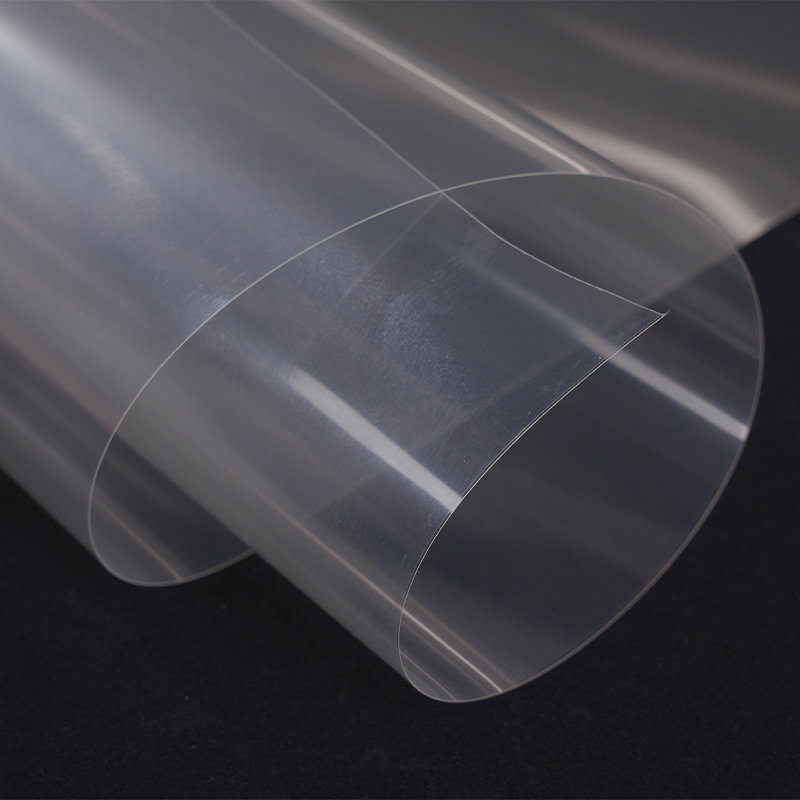

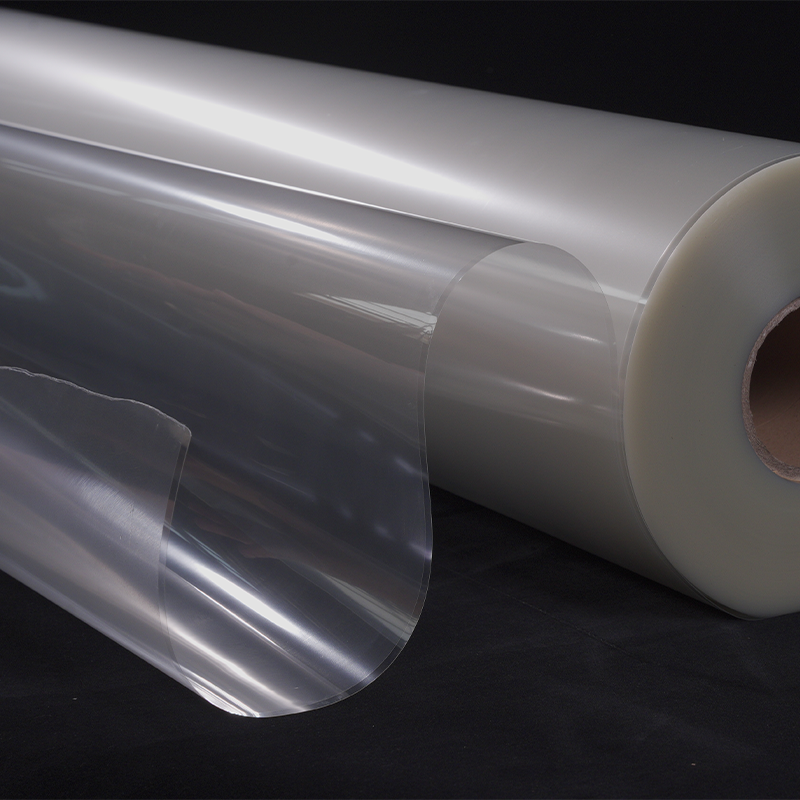

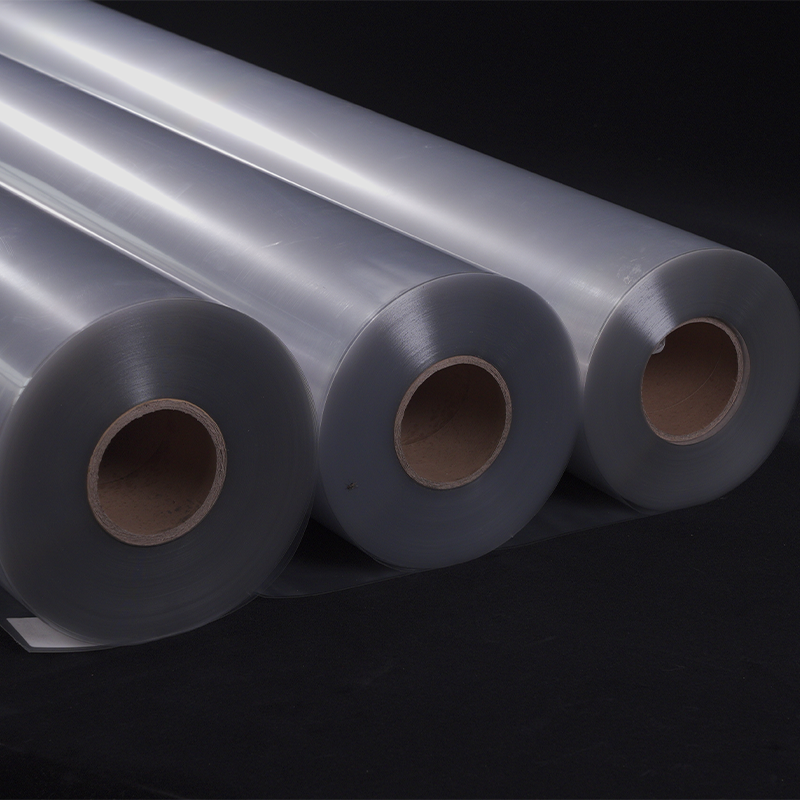

High transparency and high brightness PET rolls, with their transparency close to glass, mirror like glossiness, excellent physical and mechanical properties, good chemical stability, and excellent processing adaptability, have become one of the preferred materials for pursuing high-end appearance, clear display of content, and good protective applications.