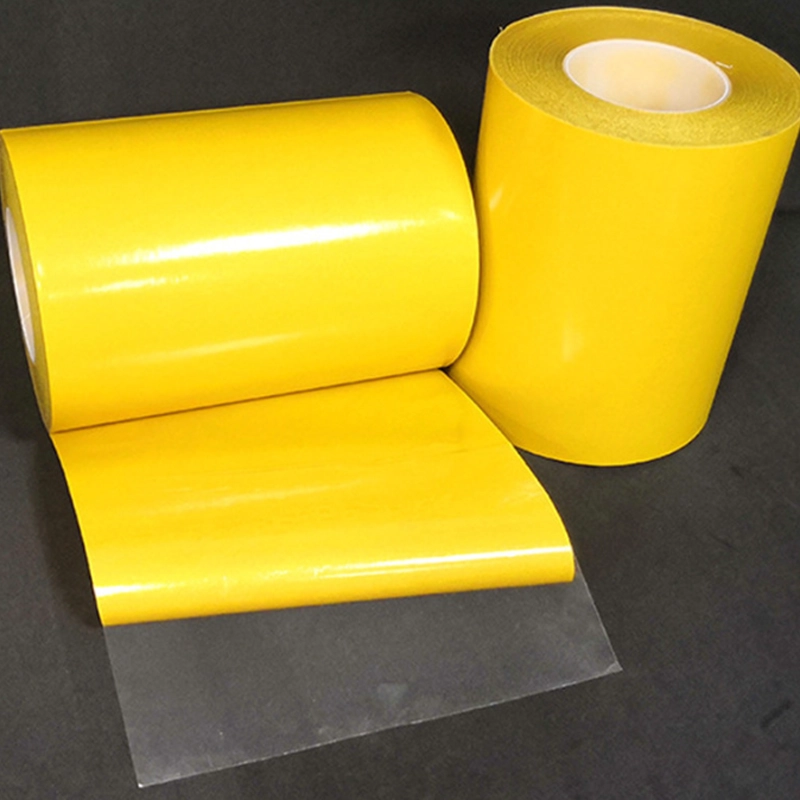

PET super transparent double-sided adhesive is a type of double-sided adhesive product that uses high-performance PET film as the substrate, with excellent transparency and good physical and chemical properties. Its “invisible” bonding properties make it an ideal choice for applications that require high transparency, reliable bonding, and weather and temperature resistance, especially in electronic products, advertising signs, and precision manufacturing