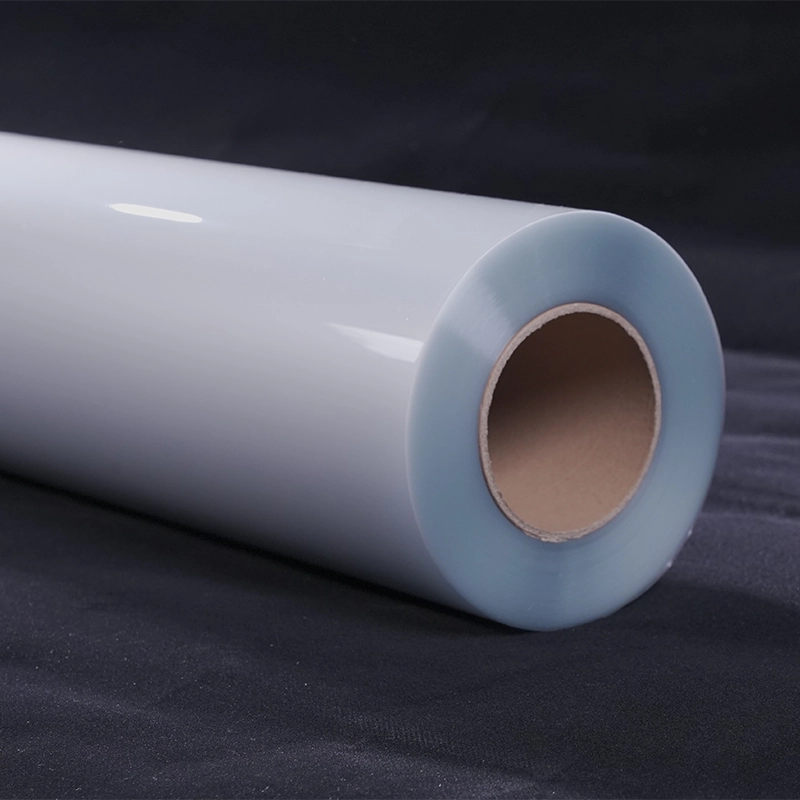

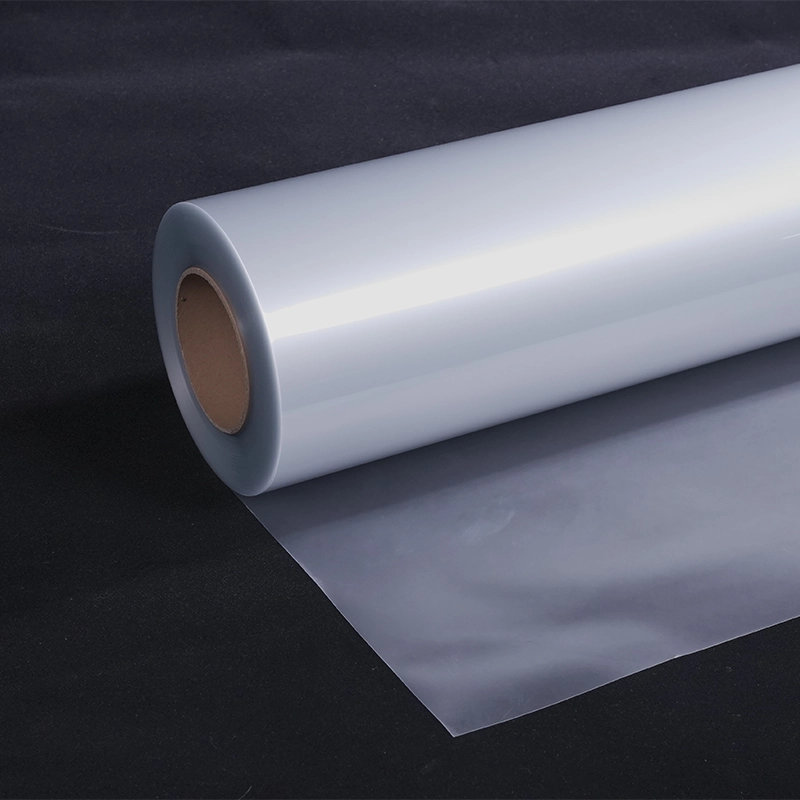

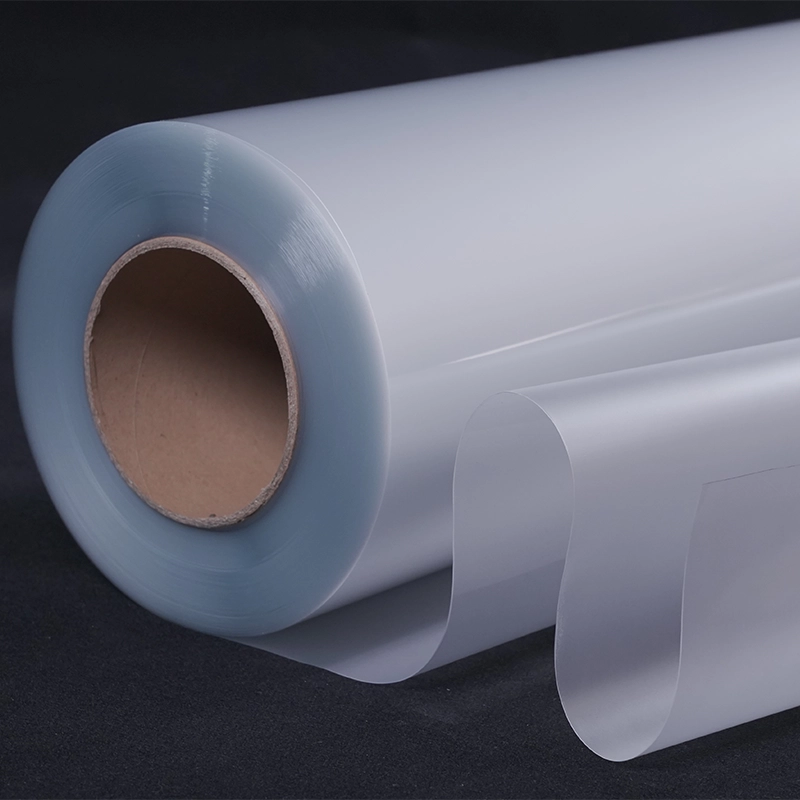

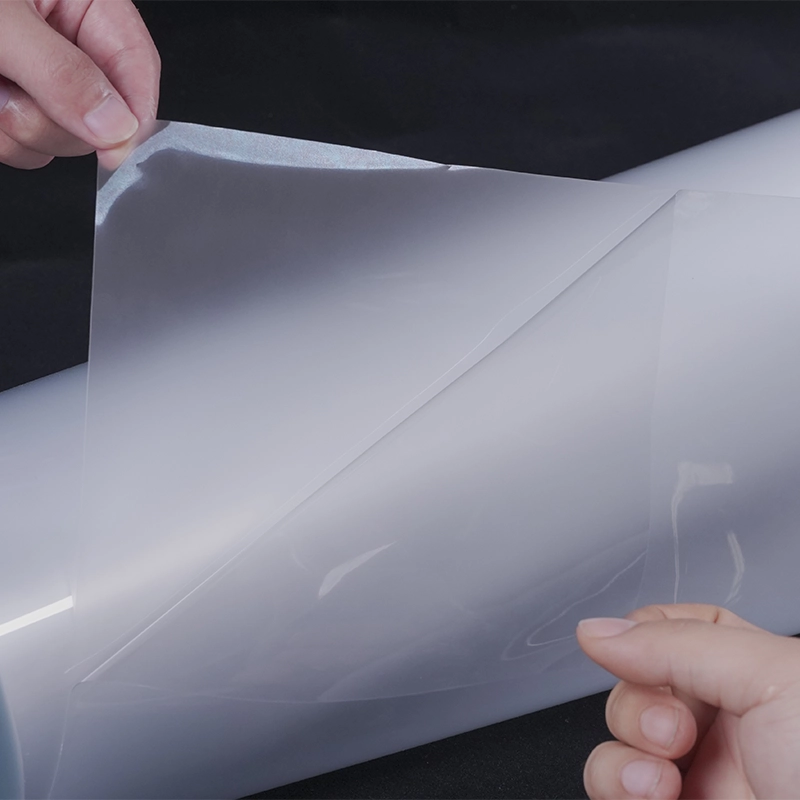

Skin sensitive optical PET pre coating is a functional film that combines an optical transparent layer and a skin sensitive coating on a PET base film through precision coating technology. Replacing traditional laminating techniques, achieving a three in one upgrade of “visual transparency+delicate touch+efficient processing”.