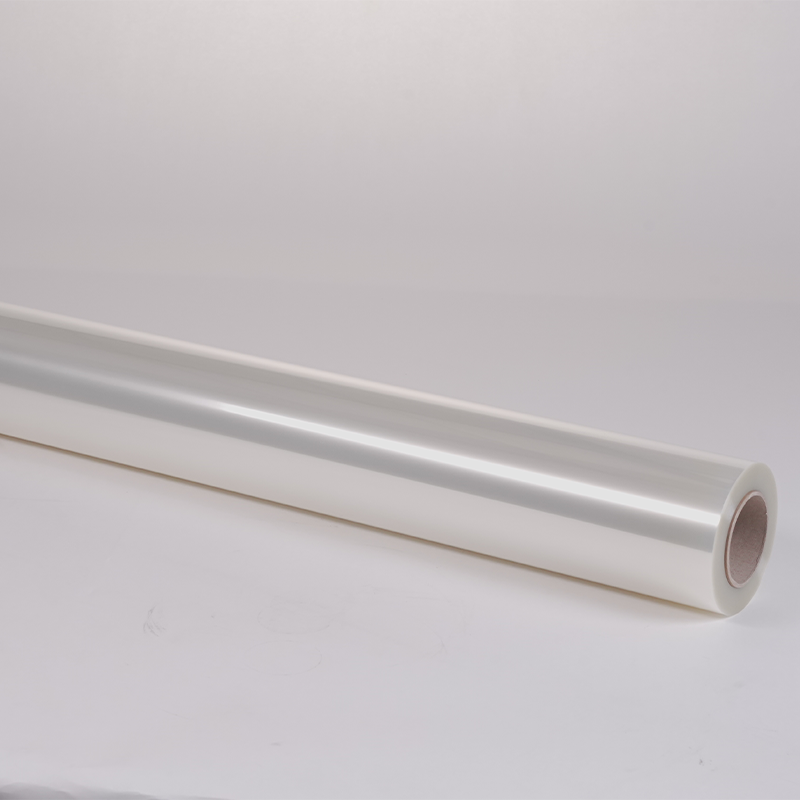

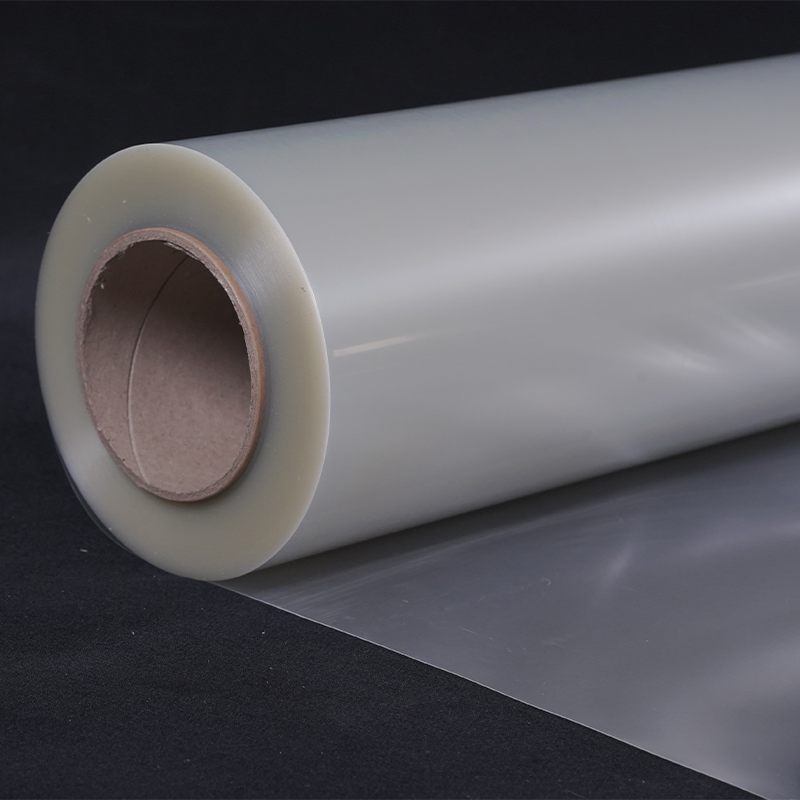

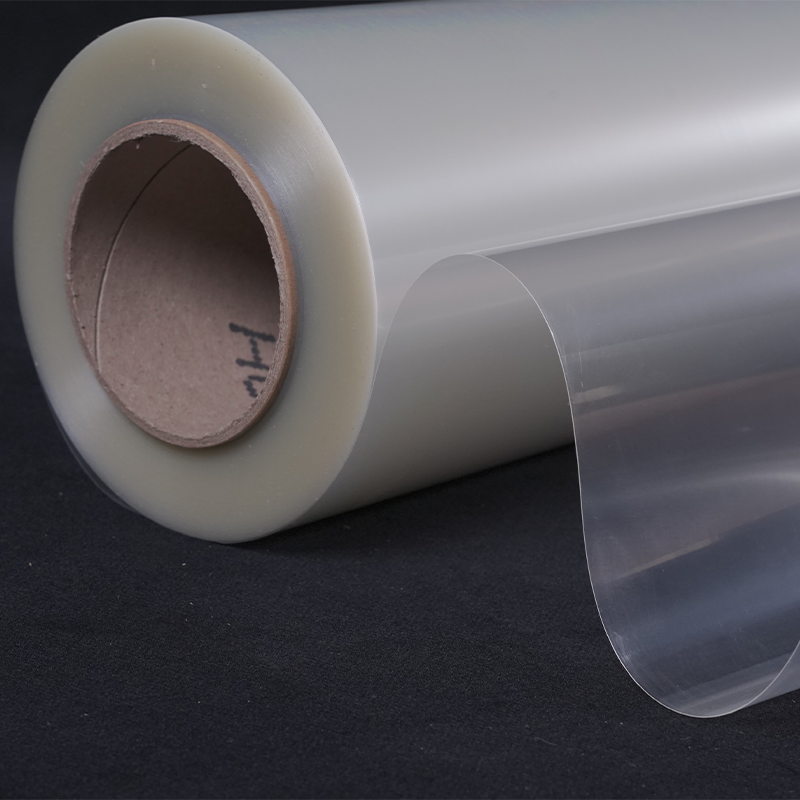

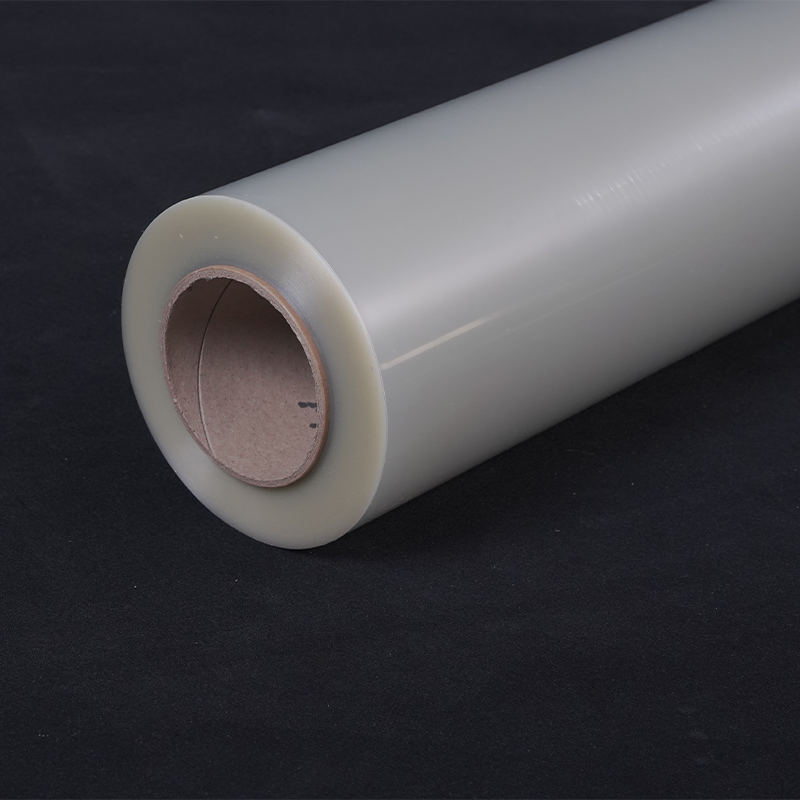

Tempered frosted PET roll is a functional decorative material that perfectly combines the excellent physical properties of PET film, the high wear resistance of hardened coatings, and the elegant texture of frosted surfaces. Its characteristics include wear resistance, scratch resistance, fingerprint resistance, matte texture, easy processing, and strong decorative properties.