What are the Components of Printable Adhesive Film? Buyer’s Concise Guide

Printable Adhesive Vinyl is the most commonly used material in the advertising printing industry today. From customized stickers and product labels to wall decorations and car body films, its applications are almost ubiquitous. Whether for commercial use by enterprises or personal DIY, adhesive film can meet diverse needs. As a buyer, it is crucial to understand the composition, types, application scenarios, and purchasing points of the appropriate materials. This article will provide you with a comprehensive analysis of printable adhesive film.

Table of Contents

ToggleWhat is Printable Adhesive Film?

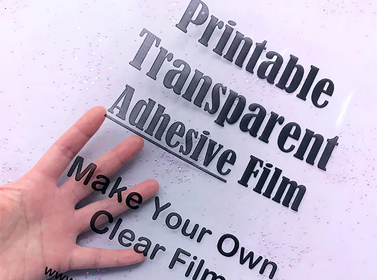

Printable adhesive film is a flexible film material that can be printed using inkjet, solvent, weak solvent, UV, or latex printers. One side has a printable coating, and the other side has adhesive, which can be firmly attached to substrates such as glass, metal, plastic, wood, or walls. It has the characteristics of strong customizability, easy operation, and durability, so it is widely used in the fields of advertising, decoration, and packaging.

The Main Structure of Printable Adhesive Film

The adhesive film is composed of multiple parts, and each layer determines its performance:

1. Vinyl Film

The top layer is usually made of PVC (polyvinyl chloride), and some high-end products also use PET film. The surface material determines the surface effect (gloss, matte, transparent) as well as durability and printing effect.

2. Adhesive Layer

This is a key part of achieving the pasting effect, and there are different choices for different purposes:

Permanent adhesive: Strong adhesion, suitable for long-term outdoor use.

Removable adhesive: can be easily removed within a certain period of time without leaving any residue, suitable for short-term advertising.

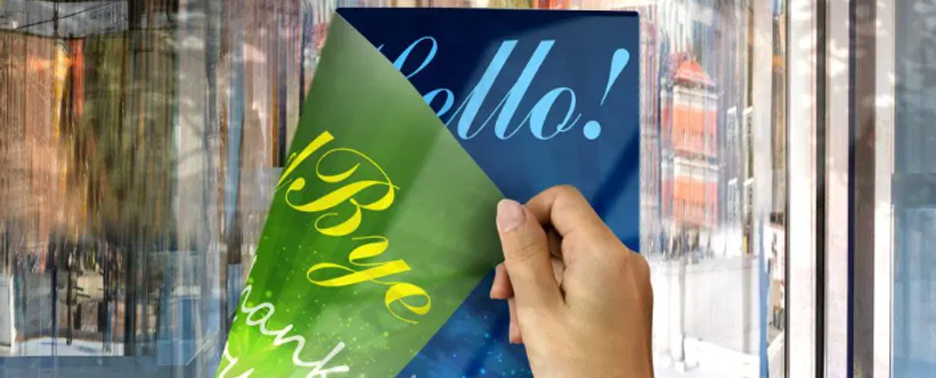

Electrostatic adsorption: No need for glue, mainly used for window advertising and short-term display.

3. Release Liner

The release paper used to protect the adhesive is mostly Gracin paper or PET release film. It not only protects the adhesive layer, but also ensures smooth paper flow in the printer.

4. Surface Coating

- In order to improve printing quality, there are often specialized coatings on the surface:

- Ink absorbing coating: ensuring color saturation and clear image.

- Scratch resistant and wear-resistant coating: enhances surface durability.

- UV resistant coating: enhances outdoor weather resistance.

- Waterproof coating: Ensure that the image is not affected by moisture.

Types of Printable Adhesive Film

According to different needs, the common types in the market are:

White glossy film: With high glossiness and vivid color reproduction effect, it is currently the most common type. Suitable for advertising stickers, brand labels, trademark printing, etc., especially for application scenarios that require visual impact. In the retail industry, food packaging, and promotional advertising, white glossy film can ensure color saturation and image clarity.

White matte film: The surface is non reflective and can reduce glare interference under light or sunlight. It is suitable for indoor display and home decoration, such as wall stickers, office signs, and art stickers. The matte effect makes the image appear softer and more suitable for showcasing photography and art works.

Transparent film: Based on transparent PVC, it still has strong transparency after printing and is widely used in glass stickers, window advertisements, car window stickers and other scenes. Transparent film can achieve a visual effect of only displaying patterns without showing the background color, which is very suitable for advertising designs that need to be integrated with the environment, such as store logos and business hour stickers.

Weather resistant/UV resistant outer film: Designed specifically for outdoor applications, it has excellent sun resistance, waterproofing, and weather resistance capabilities. Commonly used for vehicle advertising, outdoor posters, bus billboards, etc. Its anti UV coating can effectively extend the lifespan of the image and avoid fading due to prolonged exposure to sunlight.

Application Scenarios

The printable adhesive film can cover almost all visual communication and advertising display fields, with an extremely wide range of applications:

1. Commercial Brand

Adhesive backing film is a common material used by enterprises for brand promotion and packaging decoration. It can be used for product labels, logo stickers, barcode labels, QR code labels, and packaging sealing stickers. Whether it’s food and beverage, cosmetics, daily necessities, or electronic products, brand image and product recognition can be enhanced through customized labels. The adhesive film also supports small batch customization, suitable for flexible promotion by emerging brands and e-commerce sellers.

2. Advertising Promotion

Back adhesive film is an important carrier for advertising and promotion in retail stores, shopping centers, supermarkets, and exhibition venues. It can be used for window advertising, exhibition display panels, promotional posters, POP display stands, etc. Due to its easy installation and clear and vivid images, adhesive film is often used to carry limited time promotional information and new product promotions, helping businesses attract consumers’ attention in the first place.

3. Interior Decoration

Printable adhesive film is not only used in the commercial field, but also widely used for personalized decoration in home and office environments. For example, wall stickers, children’s room decoration stickers, artwork printing, office cultural walls, etc. Compared with traditional decorative materials, adhesive film is more affordable and easier to replace. Users can change the pattern at any time according to the season or mood, achieving diversified atmosphere creation in the space.

4. Vehicle Advertising

Car film is a major highlight application of adhesive film. Whether it’s bicycle advertising, taxis, buses, or corporate fleet brand image display, adhesive film can achieve large-scale and long-lasting advertising effects. Car body stickers can not only enhance brand exposure, but also protect the car paint. Choosing weather resistant and UV resistant film can ensure that vehicle advertisements remain bright for a long time in outdoor environments.

5. Activity Arrangement

Back adhesive film can quickly achieve spatial layout in exhibitions, concerts, promotional activities, or holiday celebrations. It can be used for stage background, floor mounted signage, temporary signage, and event theme decoration. The back adhesive film is easy to install and remove, making it very suitable for short-term activities. For example, floor stickers can guide the audience’s route, while stage background stickers can enhance the atmosphere of the event.

6. Education and Public Sector

Adhesive films are also widely used in schools, libraries, museums, and public facilities. It can be used for bulletin board information release, teaching chart display, public welfare promotion, and directional signage. Due to its waterproof and scratch resistant properties, the adhesive film is also suitable for high traffic areas.

Conclusion

Printable adhesive film has become a core material in the advertising, printing, and decoration industries due to its versatility and high cost-effectiveness. Understanding its structure, type, and application can help buyers choose suitable products more scientifically. When purchasing, it is recommended to prioritize product quality, weather resistance, and printing compatibility, and cooperate with reliable suppliers to achieve better printing results and higher market competitiveness.